By Advanced Hermetic Solutions • April 18, 2025 • Engineering

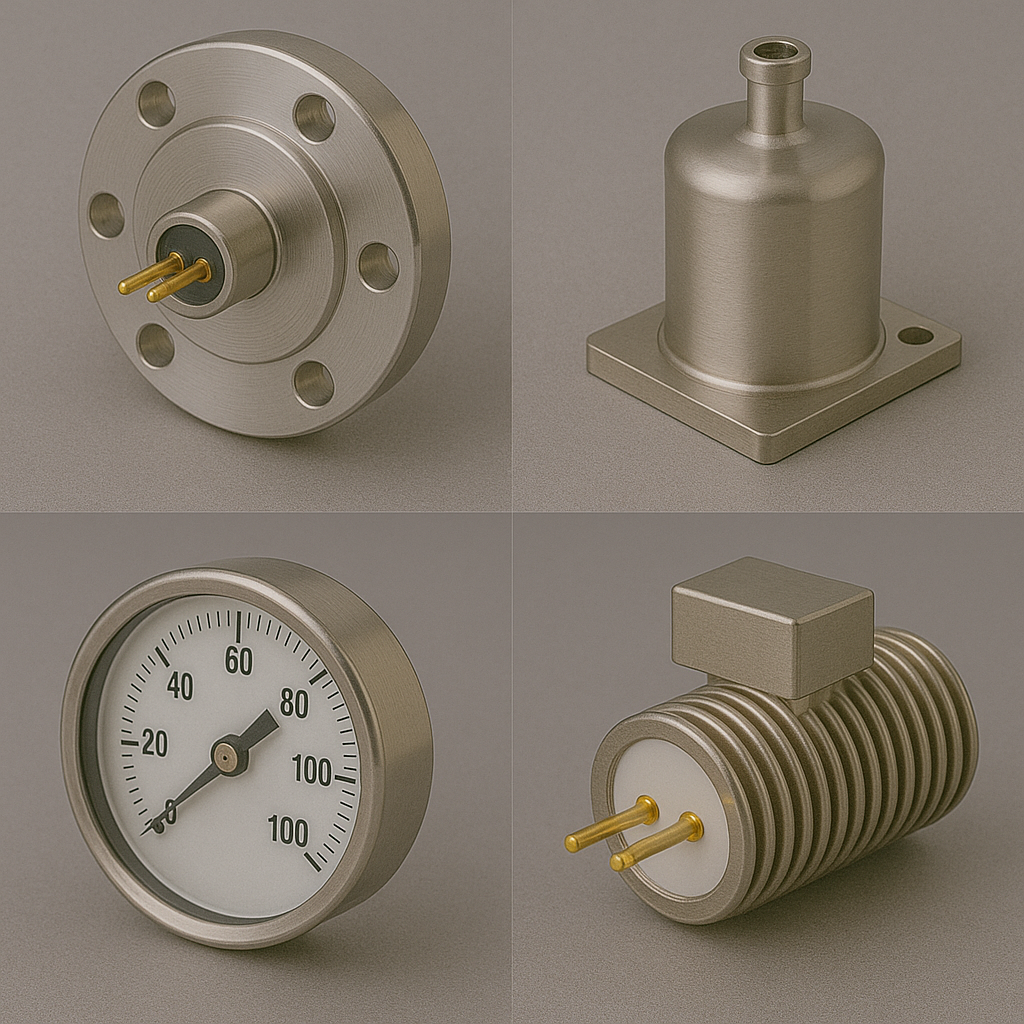

Hermetic connectors play a critical role in sealing and routing signals or power through pressurized, corrosive, or vacuum environments. Applications range from defense-grade enclosures and deep-sea sensors to medical implants and aerospace guidance systems.

Common materials include Kovar (for its CTE match to ceramics and glass), 316L stainless steel, and ceramic feedthroughs (alumina). Connectors often use gold- or nickel-plated contact pins for corrosion resistance.

Precision design of hermetic connectors ensures mission reliability under extreme conditions. AHS offers customizable connector solutions engineered for rugged performance and tested under MIL-STD and ASTM hermeticity standards.